Explore a collection of patented innovations created by Michigan Tech inventors below.

For the most up-to-date information about these patents, including the availability of Certificates of Correction, be sure to check the United States Patent and Trademark Office's free, publicly accessible database: Patent Public Search https://ppubs.uspto.gov/pubwebapp/static/pages/landing.html

-

Magnetic solvent extraction

Jiann-Yang Hwang

Particles of a magnetic material coated with a hydro- phobic surfactant are dispersed in an organic solvent extractant to produce a magnetic solvent extractant which can be used in solvent extraction processes. Phase separation of an organic phase, carrying the component to be separated, from the aqueous phase can be accelerated by applying a magnetic field to the organic phase. After removal of the organic phase, a magnetic field can be applied to the aqueous phase to remove any residual organic phase and thereby enhance the degree of separation.

-

Method of making high strength articles from forged powder steel alloys

Alfred A. Hendrickson and Darrell W. Smith

High strength steel parts or articles are made from a powder alloy by compacting the powder into a preform, sintering the preform in a sintering furnace or the like under a highly-reducing atmosphere and at a temperature of at least 1150° C., cooling the preform, preheating the sintered preform in a highly-reducing atmosphere, such as an inert gas-based atmosphere containing hydrogen or pure hydrogen, to a temperature of at least 1000° C. and transferring the preheated preform to an impact forging device and impacting the preform at a peak averaging forging pressure of at least about 1000 MPa to obtain a forged part or article. The time period between removal of the preheated preform from the preheater and the first forging impact is no more than about 8 seconds. The sintering and preheating steps can be combined with the sintered preform being cooled to the preheating temperature in the sintering furnace and transferred directly from the sintering furnace to the impact forging device.

-

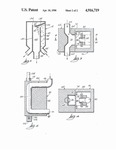

Method for compression molding articles from lignocellulosic materials

Robert D. Palardy, Bruce A. Haataja, and Andrew D. Williams

Flakeboard or particle board panels and other composite articles made from wood flakes or other particulate lignocellulosic materials having a relatively high internal bond and improved resistance to moisture are made from flakes or particles which have a moisture content of at least 15%. A catalyst capable of accelerating the reaction between the flakes or particles, the binder and water is applied to the flakes or particles prior to the addition of a moisture-tolerant particle board binder, such as an organic polyisocyanate. A mat of the resulting furnish is compression shaped under pressure and at a temperature less than 250° F. for a time period sufficient to form a composite article of the desired shape and/or dimensions.

-

Process for the extracting oxygen and iron from iron oxide-containing ores

Surendra K. Kawatra and Timothy C. Eisele

Oxygen and metallic iron are produced from an iron oxide-containing mineral, such as ilmenite, by extracting iron from the mineral with hydrochloric acid, separating solid residue from the resulting solution and drying same, electrolyzing the separated, iron chloride- containing solution to produce electrolytic iron and chlorine gas, combining the chlorine gas with water recovered from the drying and/or iron chloride-containing solution electrolysis steps of regenerate hydrochloric acid and recycling the hydrochloric acid to the extraction step. In an alternate embodiment, the chlorine gas is reacted with recovered water in the presence of a catalyst to produce hydrochloric acid which is recycled to the extraction step, thereby eliminating the need for water electrolysis and a separate hydrochloric acid regeneration step. In another alternate embodiment, electrolysis of the iron chloride-containing solution is operated to produce oxygen instead of chlorine gas at the anode and hydrochloric acid is generated concurrently with plating of iron at the cathode. This hydrochloric acid is recycled to the extraction step, thereby eliminating the need for water electrolysis and a separate hydrochloric acid regeneration step.

-

Method for treating wood against fungal attack

Peter E. Laks

Complexes of sulfited tannin extract and a copper(II) ion effectively protect wood against fungal attack. The complex can be impregnated into wood in a single step treatment using a water/organic solvent system, or formed in situ by treating the wood with an aqueous solution containing the extract and subsequently treating the wood with an aqueous solution containing a copper (II) salt.

-

Method for forming articles having deep drawn portions from matted wood flakes

Gordan R. DeBruine, Bruce A. Haataja, and L. Bogue Sandberg

An article having non-planar portions, such as a material handling pallet, including a substantially flat deck member and a plurality of hollow leg members projecting integrally from the deck member, is molded as a one-piece unit from a loosely-felted mat formed from a mixture of resinous particle board binder and flake-like wood particles. The leg members are preformed in a separate preform mold or the article forming mold and the mat is deposited on the female die over mold cavities containing the preforms. When the article forming mold is closed, the mat and preforms are compressed into substantially the desired shape and size under temperature and pressure conditions which bond the wood particles of the mat and the preforms together to form a unitary structure.

-

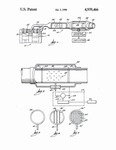

Method and apparatus for sensing the regeneration of a diesel engine particulate trap

John H. Johnson and Peter V. Woon

A diesel engine exhaust system is provided with a particulate trap for collecting the products of incomplete combustion during the engine power cycle. A sensing mechanism including an electrode downstream of the trap and a signal generating circuit provides a positive indication of occurrence of regeneration of the trap. Charged particles generated during regeneration induce a charge of the electrode, that charge activates the signal generating circuit and it, in turn, produces an indication external of the exhaust system that trap regeneration is occurring. That indication can be in the operator’s compartment.

-

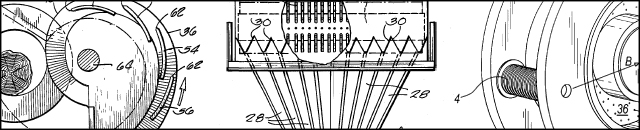

On-line analysis of ash containing slurries

Surendra K. Kawatra, Lawrence L. Sutter, and Timothy C. Eisele

The ash content of coal suspended in a slurry is determined by bombarding a sample of the slurry flowing past a window of a measuring chamber with radiation from an annular nucleonic source, such as Cm-244, for emitting radiation within the range of about 7 to about 30 KeV and causing the sample to emit both backscat- tered and iron fluorescent x-rays. These x-rays are detected by a radiation detector which produces first and second electrical signals representative of the intensity of each. The density of the sample flowing from the measuring chamber is measured, such as by a nucelonic density gauge, to produce an electrical signal representative of the density and the ash content is determined from the detected intensities of the backscattered and iron fluorescent x-rays and the sample density.

-

Biocidal treatment of materials with catechins

Peter E. Laks

Sulfide derivatives of catechins derived from condensed tannins have broad spectrum biocidal characteristics. Epicatechin-4-alkylsulfides and cupric complexes thereof containing up to 20, preferably 5 to 15, carbon atoms are particularly effective biocides against wood rotting fungi and gram-positive bacteria. Such sulfides are prepared by reacting condensed tannin, either in the form of a purified tannin extract or comminuted plant tissue, with an appropriate thiol under mild acidic conditions.

-

Method of magnetizing nonmagnetic materials

Jiann-Yang Hwang

Particles of a nonmagnetic material are rendered magnetic by contacting their surfaces with a magnetizing reagent comprising water containing particles of a magnetic material, each of which has a two layer surfactant coating including an inner layer and an outer layer. The inner layer covers the magnetic particle and is a mono- molecular layer of a first water soluble, organic, hetero- polar surfactant containing at least 3 carbon atoms and having a functional group on one end which bonds with the magnetic particle. The outer layer coats the inner layer and is a monomolecular layer of a second water soluble, organic heteropolar surfactant containing at least three carbon atoms and having a hydrophobic end bonded to the hydrophobic end of the first surfactant and a functional group on the other end capable of bonding with the particles to be magnetized.

-

Reagents for magnetizing nonmagnetic materials

Jiann-Yang Hwang

Particles of a nonmagnetic material are rendered magnetic by contacting their surfaces with a magnetizing reagent comprising water containing particles of a magnetic material, each of which has a two layer surfactant coating including an inner layer and an outer layer. The inner layer covers the magnetic particle and is a mono- molecular layer of a first water soluble, organic, hetero- polar surfactant containing at least 3 carbon atoms and having a functional group on one end which bonds with the magnetic particle. The outer layer coats the inner layer and is a monomolecular layer of a second water soluble, organic heteropolar surfactant containing at least three carbon atoms and having a hydrophobic end bonded to the hydrophobic end of the first surfactant and a functional group on the other end capable of bonding with the particles to be magnetized.

-

Method for forming a pallet with deep drawn legs

L. Bogue Sandberg, Bruce A. Haataja, Douglas C. Jurmu, Robert D. Palardy, Frank H. Story, and WIlliam A. Yates

A method for molding articles such as pallets from flake-like wood particles mixed with binder, the pallets housing a deck and integral molding legs. A loosely fitted mat of wood flakes is formed by depositing a first plurality of layers of wood flakes onto a supporting surface with a flake aligners provided for causing alignment of those flakes which will form legs of the pallet. A second plurality of layers are formed with a flake aligner provided for causing alignment of flakes which will form the legs of the pallet and in a direction transverse to the direction of alignment of the flakes of the first layers.

-

Biocidal derivatives of catechins

Peter E. Laks

Sulfide derivatives of catechins derived from condensed tannins have broad spectrum biocidal characteristics. Epicatechin-4-alkylsulfides and cupric complexes thereof containing up to 20, preferably 5 to 15, carbon atoms are particularly effective biocides against wood rotting fungi and gram-positive bacteria. Such sulfides are prepared by reacting condensed tannin, either in the form of a purified tannin extract or comminuted plant tissue, with an appropriate thiol under mild acidic conditions.

-

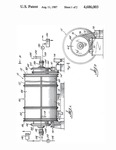

Precipitation of scale-forming materials from solution

William A. Hockings and Duane M. Thayer

Scale-forming metal oxides and carbonates, such as cupric oxide, can be precipitated from an ammoniacal leaching solution with minimum scale buildup by distilling the solution in an externally heated distillation chamber mounted for rotation about a generally horizontal axis. The distillation chamber includes a plurality of axially spaced annular baffles defining a plurality of compartments containing a tumbling medium, such as spherical balls. The solution is continuously introduced into the inlet end of the chamber and heated under pressure to a temperature above its boiling point as it flows over the baffles toward the outlet end of the chamber. A slurry containing the precipitated cupric oxide is continuously withdrawn from the outlet end and the evaporated gases are continuously withdrawn from the inlet end. The balls rub against each other, the interior of the chamber, and the sides of the baffles, as the chamber is rotated at a non-centrifuging speed, to provide a grinding or scrubbing action which minimizes a scale buildup of the precipitating cupric oxide.

-

Hydrocarbon fuel additives and method for preparing same

G. David Mendenhall and Hsiang T. Chen

A compound having the general formula R*COH[- CORJj,, wherein R is a lower alkyl hydrocarbon radical, y is 0 or 1, and x is 2 when y is 1 and 3 when y is 0, is prepared by admixing carbon monoxide, a transition metal halide, and an organomonolithium compound or an anionic equivalent thereof.

-

Column froth flotation

David C. Yang

The froth flotation device includes a flotation column partially filled with a packing which defines a large number of small flow passages extending in a circuitous pattern between the upper and lower portions of the column. A conditioned aqueous pulp of a mineral ore, such as iron ore, is introduced into the midzone of the column. A pressurized inert gas, such as air, is introduced into the bottom of the column and is forced upwardly through the flow passages in the packing. As the air flows upwardly through these flow passages, it is broken into fine bubbles which intimately contact the floatable particles (e.g., iron oxide) in the aqueous pulp and forms a froth concentrate or float fraction which overflows from the top of the column. Wash water is introduced into the top of the column and flows through the flow passages in the packing countercur- rently to the float fraction to scrub entrained non-floata- ble particles (e.g., gangue) from the froth concentrate. A tailing fraction containing the non-floatable particles is withdrawn from the bottom of the column.

-

Process for recovering terephthalic acid from waste polyethylene terephthalate

Richard A. Lamparter, Bruce A. Barna, and David R. Johnsrud

Terephthalic acid (TPA) is recovered from used polyethylene terephthalate beverage containers by reacting comminuted containers in a reaction zone with an aqueous medium containing ammonium hydroxide at elevated temperatures and pressures to form a water soluble diammonium salt of TP A, separating any undissolved solids from the reaction product, acidifying the remaining reaction product to liberate TP A, and separating the precipitated TPA. A portion of the liquid remaining after separation of TPA can be mixed with lime or slaked lime, the resulting mixture treated in an ammonia stripper to remove ammonia therefrom and the ammonia overheads from the stripper blended with another portion of the liquid remaining after separation of TPA to form a stream containing ammonium hydroxide which is recycled to the reaction zone. Ethylene glycol can be recovered from the bottoms from the ammonia stripper by distillation.

-

Self-reducing iron oxide agglomerates

Mehmet A. Goksel

Self-reducing agglomerates of an iron oxide-containing material, such as an iron ore concentrate, having a compressive strength of at least about 100 lbs. are produced by preparing a moistened mixture of the ore concentrate, a finely-divided natural pyrolyzed carbonaceous material having a volatile matter (on dry basis) content of about 20 weight % or less in an amount at least sufficient to reduce all the iron oxide to metallic iron, about 1 to about 30 weight % of a bonding agent, such as burned or hydrated lime, and 0 up to about 3 weight % of a siliceous material (as SiC>2), such as silica; forming green agglomerates from this mixture; and hydrother- mally hardening the green agglomerates by contacting them with steam under pressure.

-

Flake aligner including reciprocating baffles

Tauno B. Kilpela

Apparatus for forming a loosely felted mat of elongated wood flakes, the wood flakes being aligned in parallel relation and parallel to the longitudinal direction of the mat. The apparatus includes a former for depositing wood flakes on a support surface in a uniformly dispersed, loosely felted relation, and a plurality of vertically oriented baffles positioned below the former and in mutually parallel alignment. The baffles are reciprocated in the direction of the mat to cause flakes lying across the baffles to fall between the baffles and to be aligned with the longitudinal direction of the mat.

-

Apparatus for forming mat of aligned flake composite wood material with continuous baffles

Gordon P. Krueger, Anders E. Lund, and Roy D. Adams

An apparatus is provided for forming a continuous loosely felted mat of wood flakes, the wood flakes being elongated and being aligned in mutually parallel relation and parallel to the longitudinal axis of the mat. The apparatus includes a conveyor having an upper surface adapted to support a mat of wood flakes and formers for continuously depositing wood flakes on the conveyor as it moves under the former. Also included are continuous lengths of baffle material positioned between the formers and the conveyor, and oriented so as to define parallel adjacent vertical planes, the planes being parallel to the direction of movement of the upper surface. The lengths of baffle material are positioned in closely spaced side-by-side relation and move with the upper surface beneath the formers as the loosely felted mat is formed and are adapted to cause the flakes to become aligned and to be held in alignment during formation of the mat.

-

Fan-shaped loader for making a loosely felted mat of aligned wood flakes

Gordan P. Krueger, Anders E. Lundi, and Roy D. Adams

Apparatus for forming an elongated continuous mat of elongated wood flakes mixed with a binder and adapted to be compressed to form a densified composite wood product for continuously depositing wood flakes on that supporting surface and for aligning the elongated wood flakes being deposited in mutually parallel relation and in alignment with the direction of movement of the supporting surface. A hopper for containing wood flakes deposits wood flakes into the upper end of a fan-shaped flake loader comprised of a plurality of channels positioned in side-by-side relation and sloping downwardly from the hopper to a supporting surface. The channels are generally V-shaped in cross-section and converge toward their lower ends such that the wood flakes deposited in the upper ends of the channels become aligned in mutually parallel relation as the flakes slide down the channels and are deposited on the supporting surface.

-

Flake feeder aligner including reciprocating baffles

Tauno B. Kilpela

Apparatus is described for forming a loosely felted mat of elongated wood flakes, the wood flakes being aligned in parallel relation and parallel to the longitudinal direction of the mat. The apparatus includes a former for depositing wood flakes on a support surface in a uniformly dispersed, loosely felted relation, and a plurality of vertically oriented baffles positioned below the former and in mutually parallel alignment. The baffles include a first set and a second set with respective ones of the second set of baffles being positioned between respective ones of the baffles of the first set. The baffles of the second set are reciprocated in the direction of the mat to cause flakes lying across the baffles to be aligned with the longitudinal direction of the mat.

-

Static dropless flake aligner for producing composite wood material

Gordan P. Krueger, Anders E. Lund, and Roy D. Adams

Apparatus are provided for forming a loosely felted mat of elongated wood flakes, the wood flakes being supported on an elongated caul. The flakes are deposited between a plurality of closely spaced parallel baffles so as to be aligned in mutually parallel relation. The caul is supported adjacent the lower edges of the baffles and is support for vertical movement to facilitate buildup of the mat. Apparatus movable back and forth along the length of the caul is provided to deposit wood flakes in an evenly dispursed manner. At least one picker wheel also moves along the length of the baffles, the picker wheel including fingers extending downwardly between baffles and adapted to engage the flakes to cause them to fall between the baffles.

-

Apparatus for making continuous lengths of composite wood material, the apparatus including rotating circular baffles

Anders E. Lund, Gordon P. Krueger, Bruce A. Haataja, and Roy D. Adams

Apparatus for forming an elongated loosely felted mat of thin elongated wood flakes with the flakes being aligned in mutually parallel relation and being aligned with the longitudinal direction of the elongated mat. The apparatus comprises a plurality of conveyor belts positioned in closely adjacent side-by-side relation and defining a mat supporting surface adapted to support the aligned wood flakes, the belts being supported on the surface of a cylinder. Wood flakes are deposited in loosely felted relation on the belts, and a plurality of closely spaced parallel planar baffles surround the cylinder, the baffles comprising plates positioned between the belts and functioning to cause alignment of the flakes as they are deposited on the belts. The mat is compressed against the supporting surface by a plurality of belts positioned in adjacent side-by-side relation, the belts being positionable between the baffles and engage- able against the mat.

-

Multiple funnel flake aligner for making a loosely felted mat of aligned wood flakes

Bruce A. Haataja, Tauno B. Kilpela, Gordon P. Krueger, and Roy D. Adams

Apparatus for forming a loosely felted mat of thin elongated wood flakes with said flakes being aligned in mutually parallel relation. The apparatus includes a mat supporting surface, a hopper for holding a quantity of wood flakes, and a funnel assembly for receiving wood flakes from the hopper and for causing the flakes to be aligned in substantially parallel side-by-side relation as they are deposited on the supporting surface. The funnel assembly includes a plurality of funnels positioned in adjacent side-by-side relation, the funnels each including inclined walls having lower edges defining an elongated narrow opening adjacent the supporting surface and upper edges defining an opening wider than said narrow opening and for receiving wood flakes from the hopper. The narrow openings of the funnels are parallel and distribute the flakes uniformly across the supporting surface.