Explore a collection of patented innovations created by Michigan Tech inventors below.

For the most up-to-date information about these patents, including the availability of Certificates of Correction, be sure to check the United States Patent and Trademark Office's free, publicly accessible database: Patent Public Search https://ppubs.uspto.gov/pubwebapp/static/pages/landing.html

-

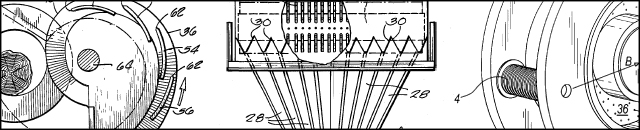

Method for reducing macrosegregation in alloys

Angus Hellawell

Macrosegregation in metal alloy castings and other alloys having similar solidification behavior is reduced by slowly rotating a mold or the like containing the liquid alloy about an axis at an acute angle to the vertical from the time the liquid alloy is poured into the mold until substantially all of the alloy has solidified. The mold is rotated at a speed below that which produces a centrifuging effect or causes stirring or agitation of the interdendritic liquid.

-

Method for preparing organic hyponitrites

G. David Mendenhall

Tertiary organic hyponitrite usable as initiators for polymerizing ethylenically unsaturated compounds are prepared by reacting an alkali metal, alkaline earth, ammonium or substituted ammonium salt of hyponitrite, such as sodium hyponitrite, with a tertiary organic halide, such as tert-butyl chloride, in the presence of one or more weak Friedel-Crafts catalysts, such as ferric or zinc chloride, and in a solution of a neutral solvent.

-

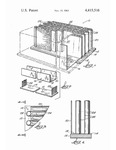

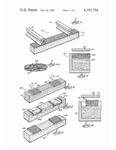

Flake aligner including baffles supported on continuously moving conveyor

Anders E. Lund, Gordon P. Krueger, Lynn B. Sandberg, and Roy D. Adams

Apparatus for forming a continuous elongated loosely felted mat of thin elongated wood flakes with the flakes being aligned in mutually parallel interleaved relation. The apparatus includes a plurality of belts positioned in adjacent side-by-side relation and for continuous movement so as to define a supporting surface for the mat. A plurality of sets of thin planar baffle plates are provided, each set including a plurality of thin planar baffle plates supported in coplanar alignment and in edge-to-edge adjacent relation. The baffle plates are positioned between a hopper for depositing wood flakes and the supporting surface and function to align the wood flakes in substantially mutually parallel relation in substantially parallel relation to the direction of movement of the supporting surface and to maintain the wood flakes in substantially parallel alignment as the flakes fall from the hopper onto the supporting surface. Each of the sets of baffle plates are positioned between pairs of belts and are supported for movement with the belts, and the baffle plates of one set are parallel to and spaced closely adjacent to baffle plates of an adjacent set.

-

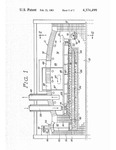

Method for molding articles having non-planar portions from matted wood flakes

Bruce A. Haataja, Tauno B. Kilpela, Anders E. Lund, and James F. Hamilton

An article having non-planar portions, such as a pallet having a substantially flat deck member and a plurality of hollow leg members projecting integrally from the deck member, is molded as a one-piece unit from a loosely-felted, layered mat formed from a mixture of a resinous particle board binder and flake-like wood particles. The wood flakes have an average length of about 11/4 to about 6 inches, preferably about 2 to about 3 inches, an average thickness of about 0.005 to about 0.075 inch, preferably about 0.015 to about 0.025 inch, and an average width of 3 inches or less and no greater than the average length. Each layer of wood flakes in the mat lie substantially flat on a plane generally parallel to the major plane thereof and are randomly oriented to each other. The mat is placed between the male and female dies of a mold or press and compressed therein to substantially the desired shape under temperature and pressure conditions sufficient to bond the flakes together.

-

Method and apparatus for making aligned flake composite wood material including integral baffles

Gordan P. Krueger, Anders E. Lund, and Roy D. Adams

A method and apparatus for forming a loosely felted mat of elongated wood flakes mixed with a binder, the mat including a longitudinal axis and the wood flakes being aligned in mutually parallel relation and parallel to the longitudinal axis of the mat. The wood flakes are held in alignment in the mat by a plurality of closely spaced thin planar baffles, the baffles being comprised of a material which can form an integral part of the mat.

-

Molded wood particle pallet having increased bending strength

Bruce A. Haataja

The invention includes a molded unitarily formed pallet comprising wood particles bonded together by a cured binder in compressed relation and forming a deck having an upper surface supporting a load, and a plurality of elongated substantially parallel spaced channels supporting the deck. The channels extend from adjacent one edge of the pallet to adjacent an opposite edge. The channels each including spaced channel side walls extending downwardly from said deck and terminating in a planar bottom wall parallel to the deck. The side walls are integrally joined at their upper edges to the deck and integrally joined at their lower edges to the bottom wall. The deck and elongated channels are formed by laying a loosely felted mat of wood particles in a press, the mat including wood flakes mixed with a binder and the wood flakes being thin and generally planar and being laid in felted relation so as to lie in substantially horizontal planes in interleaved relation, and by compressing the mat.

-

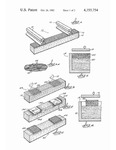

Molded wood particle products including integrally joined intersecting members

Bruce A. Haataja

A molded product formed from wood flakes intermixed with a binder and a first elongated member formed from elongated wood flakes compressed and bonded together with a binder, the wood flakes having a grain direction extending generally parallel to the longitudinal axis of the flakes and the flakes being generally oriented in alignment with the longitudinal axis of the first elongated member. A second elongated member intersects the first elongated member and is integrally joined to it. The second elongated member is also formed from elongated wood flakes compressed and bonded together with a binder, the wood flakes being generally oriented in alignment with the longitudinal axis of the second elongated member. The wood flakes of the second elongated member intersect and are interleaved with the wood flakes of the first elongated member to thereby form an integral molded joint between the first elongated member and the second elongated member.

-

Treatment during transport of solid waste

Wayne M. Fassell

The method of treatment during transport of solid waste by depositing the solid waste on the surface of a molten stream of lead traveling in one direction whereby organic material in the waste is subjected to thermal degradation, metals and other materials in the waste which are insoluble in the molten lead and of lesser specific gravity remain on the surface of the molten lead for removal and recovery while metals and other materials which are soluble in the molten lead dissolve in the molten lead for separation from the remainder while metal and materials which are insoluble in the molten lead and of higher specific gravity fall to the bottom of the stream of molten lead.

-

Structural members comprised of composite wood material and having zones of diverse density

Anders E. Lund and Gordan P. Krueger

The disclosed invention includes an improved construction of structural members such as railroad crossties, highway spin posts and highway guard posts and to construction of said members from composite wood material including elongated wood flakes and to a method for making such improved structures.

-

Pallets molded from matted wood flakes

Bruce A. Haataja, Tauno B. Kilpela, Anders E. Lund, and James F. Hamilton

An article having non-planar portions, such as a pallet having a substantially flat deck member and a plurality of hollow leg members projecting integrally from the deck member, is molded as a one-piece unit from a loosely-felted, layered mat formed from a mixture of a resinous particle board binder and flake-like wood particles. The wood flakes have an average length of about 11/4 to about 6 inches, preferably about 2 to about 3 inches, an average thickness of about 0.005 to about 0.075 inch, preferably about 0.015 to about 0.025 inch, and an average width of 3 inches or less and no greater than the average length. Each layer of wood flakes in the mat lie substantially flat on a plane generally parallel to the major plane thereof and are randomly oriented to each other. The mat is placed between the male and female dies of a mold or press and compressed therein to substantially the desired shape under temperature and pressure conditions sufficient to bond the flakes together.

-

Articles molded from papermill sludge

Bruce A. Haataja and Anders E. Lund

An article, such as a pallet having a substantially flat deck member and a plurality of hollow legs projecting from the deck member, is molded as a one-piece unit from a papermill sludge. Dried, comminuted papermill sludge is blended with a fibrous reinforcing material, preferably a cellulosic material such as fibrous bark particles, and a resinous particle board binder, the resulting mixture of furnish is formed into a loosely fitted mat, and the mat is placed between dyes of a mold and press and compressed to substantially the desired shape under temperature and pressure conditions sufficient to bond the sludge and bark particles together.

-

Carminomycin analogue

Hassan S. El Khadem and David L. Swartz

A novel anthracycline glycoside 2-deoxy-L-fucopyranosyl carminomycinone which is effective for inhibiting the growth of tumors such as leukemia L1210.

-

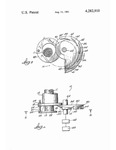

Fingerling shear

Tauno B. Kilpela and Bruce A. Haataja

A fingerling shear for shearing a length of wood in a plane transverse to the grain direction and for splitting the sheared length along the grain direction to form a plurality of fingerlings. The shear includes a planar shearing blade, supported for rotation about a generally vertical axis, the planar shearing blade including an involute cutting edge adapted to engage the elongated piece of wood during rotation of the blade and for shearing off a length of that piece of wood, and a plurality of splitting blades fixed to the lower surface of the planar shearing blade and spaced along the involute cutting edge, the splitting blades each including a leading cutting edge spaced from the involute cutting edge of the planar blade and extending tranversely to the lower surface, the cutting edges of the splitting blades being adapted to sequentially engage portions of the sheared length of the wood stock to sequentially split fingerlings from the sheared length.