Files

Download Full Text (593 KB)

Abstract

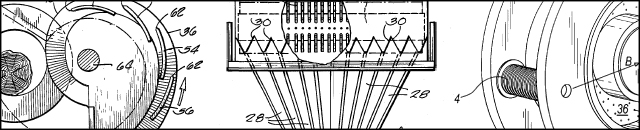

Scale-forming metal oxides and carbonates, such as cupric oxide, can be precipitated from an ammoniacal leaching solution with minimum scale buildup by distilling the solution in an externally heated distillation chamber mounted for rotation about a generally horizontal axis. The distillation chamber includes a plurality of axially spaced annular baffles defining a plurality of compartments containing a tumbling medium, such as spherical balls. The solution is continuously introduced into the inlet end of the chamber and heated under pressure to a temperature above its boiling point as it flows over the baffles toward the outlet end of the chamber. A slurry containing the precipitated cupric oxide is continuously withdrawn from the outlet end and the evaporated gases are continuously withdrawn from the inlet end. The balls rub against each other, the interior of the chamber, and the sides of the baffles, as the chamber is rotated at a non-centrifuging speed, to provide a grinding or scrubbing action which minimizes a scale buildup of the precipitating cupric oxide.

Patent Number

4,686,003

Assignee

Board of Control of Michigan Technological University, Houghton, Mich.

Application Number

445,224

Date Filed

12-10-1982

Certificate of Correction

No

Issue Date

8-11-1987

Disciplines

Engineering | Materials Science and Engineering

Recommended Citation

Hockings, William A. and Thayer, Duane M., "Precipitation of scale-forming materials from solution" (1987). Michigan Tech Patents. 51.

https://digitalcommons.mtu.edu/patents/51

Comments

For the most up-to-date information about this patent, including the availability of Certificates of Correction, be sure to check the United States Patent and Trademark Office's free, publicly accessible database: Patent Public Search https://ppubs.uspto.gov/pubwebapp/static/pages/landing.html