Files

Download Full Text (374 KB)

Abstract

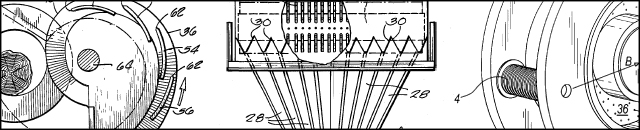

High strength steel parts or articles are made from a powder alloy by compacting the powder into a preform, sintering the preform in a sintering furnace or the like under a highly-reducing atmosphere and at a temperature of at least 1150° C., cooling the preform, preheating the sintered preform in a highly-reducing atmosphere, such as an inert gas-based atmosphere containing hydrogen or pure hydrogen, to a temperature of at least 1000° C. and transferring the preheated preform to an impact forging device and impacting the preform at a peak averaging forging pressure of at least about 1000 MPa to obtain a forged part or article. The time period between removal of the preheated preform from the preheater and the first forging impact is no more than about 8 seconds. The sintering and preheating steps can be combined with the sintered preform being cooled to the preheating temperature in the sintering furnace and transferred directly from the sintering furnace to the impact forging device.

Patent Number

5,009,842

Assignee

Board of Control of Michigan Technological University, Houghton, Mich.

Application Number

535,379

Date Filed

6-8-1990

Certificate of Correction

No

Issue Date

8-23-1991

Disciplines

Engineering | Materials Science and Engineering

Recommended Citation

Hendrickson, Alfred A. and Smith, Darrell W., "Method of making high strength articles from forged powder steel alloys" (1991). Michigan Tech Patents. 62.

https://digitalcommons.mtu.edu/patents/62

Comments

For the most up-to-date information about this patent, including the availability of Certificates of Correction, be sure to check the United States Patent and Trademark Office's free, publicly accessible database: Patent Public Search https://ppubs.uspto.gov/pubwebapp/static/pages/landing.html