Explore a collection of patented innovations created by Michigan Tech inventors below.

For the most up-to-date information about these patents, including the availability of Certificates of Correction, be sure to check the United States Patent and Trademark Office's free, publicly accessible database: Patent Public Search https://ppubs.uspto.gov/pubwebapp/static/pages/landing.html

-

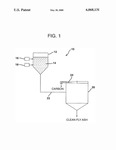

Method for removal of ammonia from fly ash

Jiann-Yang Hwang

A method for removing ammonia and ammonia compounds from fly ash and other combustion by-products is provided. The method may be performed with raw or processed fly ash, or it may be performed in conjunction with a wet beneficiation process. The method involves mixing the ammonia-contaminated fly ash with water and then filtering and/or drying the solution to remove the ammonia and water. The method produces fly ash having an ammonia content of less than about 60-80 ppm, which allows the fly ash to be utilized in a number of applications.

-

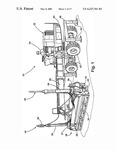

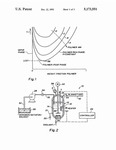

Apparatus and method for three-dimensional contouring

Carl B. Kieranen, Charles A. Hallstrom, Glen R. Simula, Nils P. Ruonavaara, and James D. Waineo

A contouring device and method for contouring three- dimensionally curved surfaces includes an elongated contouring assembly that is supported at opposite ends by a pair of fluid cylinders. The fluid cylinders are controlled to raise and lower the ends of the contouring assembly independently of each other, thereby allowing the contouring assembly to create a three-dimensionally curved surface as it passes over an area to be contoured. The control of one of the fluid cylinders is based on a comparison of the measured position of a first end of the contouring assembly with a profile of the surface to be leveled that is stored in a computer memory. The measurement of the position of the first end of the contouring assembly is achieved by a tracking device which tracks the position of a target positioned on the first end of the contouring assembly and which determines the three dimensional position of the target. A proximity sensor measures the position of the second end of the contouring assembly from a surface and outputs a control signal that adjusts the height of the second end of the contouring assembly to follow the surface. Alternatively, a second target positioned on the second contouring assembly end is tracked by a second tracking device to determine the three-dimensional position of the second end. The contouring assembly preferably has a plow, rotating auger, and a vibratory screed positioned adjacent and parallel to one another in an orientation transverse to the direction of motion of the contouring assembly. The plow, rotating auger, and vibratory screed are all pivotable about an axis parallel to their longitudinal direction. A pivot or tilting controller controls the tilting of the plow, rotating auger, and vibratory screed to follow the slope of the profile stored in computer memory.

-

Method of removing carbon from fly ash

Robert William Styron and Jiann-Yangg Hwang

A froth flotation method is provided for removing carbon from fly ash which utilizes an environmental friendly conditioning agent. The conditioning agent preferably comprises a biodegradable oil which is added to a slurry containing raw fly ash and water. The conditioning agent renders the carbon in the fly ash hydrophobic such that upon aeration of the slurry, air bubbles attach to the carbon particles and carry' them to the surface of the slurry in the form of a froth, such that the carbon may be removed.

-

Apparatus and method for the generation and use of ferric ions

Donald R. Lueking and Carl C. Nesbitt

An apparatus and method for the generation and use of ferric ions produced by acidophilic, chemoautotrophic bacteria.

-

Control of mercury emissions using unburned carbon from combustion by-products

Jiann-Yang Hwang and Zhenglong Li

Mercury emission from a flue gas such as that generated by a coal fired power plant is controlled by injecting into the flue gas unburned carbon purified from ash such as fly ash or wood ash. The unburned carbon adsorbs the mercury and is later removed from the flue gas by a particle separator. The unburned carbon collected from ash is significantly lower in cost compared to activated carbon presently used in such a process. The unburned carbon is concentrated in the sorbent by one or more separation processes used to remove noncarbon particles from the fly ash. These processes include gravity separation, electrostatic separation, froth flotation, magnetic separation and size classification. Mercury adsorption is further increased by oxidation of the carbon surface.

-

Genetic transformation and regeneration of plants

Vincent Lee C. Chiang, Chung-Jui Tsai, and Gopi K. Podila

An Agrobacterium-mediated transformation and regeneration method for plants including a transformation method to produce transgenic plants with an altered lignin composition.

-

Genetic engineering of wood color in plants

Vincent Lee C. Chiang, Chung-Jui Tsai, and Gopi K. Podila

The invention relates to genetically engineering the wood color of woody plants by incorporation of the lignin pathway gene O-methyltransferase into the genome of the plants.

-

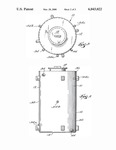

Microwave telemetry for sensing conditions in enclosed rotating and/or reciprocating machinery

Richard L. Campbell, Douglas B. Brumm, Carl L. Anderson, and Glen L. Barna

An apparatus for measuring the pressure within the torque converter of an automatic transmission. The apparatus includes a sensor to sense the interior pressure of the torque converter and generate an electrical signal representative of that pressure. That signal is converted to microwave energy which is radiated into the interior of the torque converter housing from a microwave transmitter located within the torque converter. Receiving microwave antennae exposed to the housing interior receive the microwaves and transmit an electrical signal corresponding to the microwave energy to a remote readout external of the torque converter. The receiving antenna are preferably in the form of resonant slots in the torque converter housing and the slots have a length related to the wavelength of the generated microwaves.

-

Method for producing powder from polycrystalline inorganic material

Surendra K. Kawatra and Timothy C. Eisele

A method for producing powder from polycrystalline inorganic material by contacting polycrystalline inorganic material with the vapor of one or more reduced alkali metals in an environment substantially free of oxygen for a period of time sufficient to cause disintegration of the polycrystalline inorganic material into powder. The polycrystalline inorganic material may consist of one or more oxides, sulfides, or silicates, or combinations thereof. The poly crystalline inorganic material may also comprise a rock or mineral, such as basalt or pyrite.

-

Method and apparatus for destroying organic compounds in fluid

Yin Zhang, John C. Crittenden, David W. Hand, and David L. Perram

An apparatus for the photocatalytic oxidation of organic contaminants in fluid includes a reactor and a photocatalyst affixed to support material. Preferably, the outer wall of the reactor is constructed of material transmissive of ultraviolet radiation. The support material preferably is transmissive of ultraviolet radiation. The support material can also be an adsorbent material. Also, a method for photocatalytic oxidation of organic contaminants in fluid. Also, a method for preparation of a supported photocatalyst. Also, a supported photocatalyst adapted for the photocatalytic oxidation of organic contaminants in fluid. Also, a method for preparing a photocatalyst adapted for the photocatalytic oxidation of organic contaminants in fluid.

-

Process for producing high strength alumina

James M. Staehler, William W. Predebon, and Bruce J. Pletka

A vacuum hot pressed alumina material having small, isometric grains; a uniform distribution thereof; relatively low, predominantly transgranular porosity; and a density approaching the theoretical density of pure alumina produced by vacuum hot pressing alumina powder which contains at least 98.0% alumina, is substantially free of any sintering aids or any other additives, and has a median particle size less than about 3 microns, in a vacuum hot press operated at a temperature of at least about 1350° C. and a pressure of at least 28 MPa (3500 PSI) for a sintering period of at least 1.5 hours. The vacuum hot pressed alumina material also has compressive strength, flexural strength, impact strength, and wear resistance superior to that for most conventional sintered alumina materials.

-

Fiber optic detector and depth sensor and method for doing same

Lawrence W. Evers and Kenneth J. Jackson

A fiber optic sensor for determining the presence and/or measuring the depth of a first substance capable of transmitting light. The fiber optic sensor includes a plurality of light receiving fibers, a plurality of light transmitting fibers surrounding the light receiving fibers and structure for refracting light from the light transmitting fibers at a predetermined angle for total internal reflection of the light from an interface of the first substance with a second substance.

-

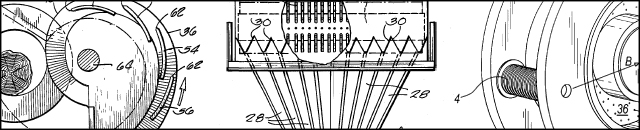

Mat forming apparatus

Bernard C. H. Sun

Mat forming apparatus comprising, in combination, a hollow material transporting member, drive structure for producing a pressure differential across spaced portions of the transporting member so that material is propelled from one of the spaced portions to the other within the hollow transporting member, material directing structure communicating with the drive structure for receiving material from the hollow transporting structure and, responsive to the drive structure, operative to direct the received material in a predetermined path, the hollow transporting member having a non-linear inner surface so that flow in the hollow transporting member is turbulent causing the material being transported therein to experience turbulent flow in being propelled from one of the spaced portions to the other, and structure associated with the material directing structure for receiving the material and confining the received material in a defined space.

-

High strength alumina and process for producing same

James M. Staehler, WIlliam W. Predebon, and Bruce J. Pletka

A vacuum hot pressed alumina material having small, isometric grains; a uniform distribution thereof; relatively low, predominantly transgranular porosity; and a density approaching the theoretical density of pure alumina produced by vacuum hot pressing alumina powder which contains at least 98.0% alumina, is substantially free of any sintering aids or any other additives, and has a median particle size less than about 3 microns, in a vacuum hot press operated at a temperature of at least about 1350° C. and a pressure of at least 28 MPa (3500 PSI) for a sintering period of at least 1.5 hours. The vacuum hot pressed alumina material also has compressive strength, flexural strength, impact strength, and wear resistance superior to that for most conventional sintered alumina materials.

-

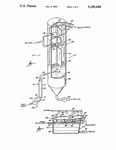

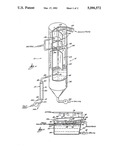

Flotation column with adjustable supported baffles

Surendra K. Kawatra and Timothy C. Eisele

An apparatus for separating by froth flotation hydro- phobic and hydrophilic particles contained in an aqueous slurry, the apparatus comprising a generally vertical tubular column having an upper froth zone, an upper separation zone, a lower separation zone, an air inlet zone, and an intermediate feed inlet zone; a feed inlet, air inlet, froth outlet and a tailings outlet; an upper baffle unit comprising a plurality of horizontally extending upper baffle plates, a vertical upper support member including an upper end portion, and first upper apparatus for removably mounting the upper baffle plates on the upper support member at predetermined vertically spaced positions; each of the upper baffle plates comprising a mounting aperture and a plurality of flow apertures; and a second upper apparatus for removably supporting the upper support member in the column with the upper baffle plates in the upper separation zone. The apparatus can include a lower baffle unit. The open area of each baffle plate and the vertical space between adjacent baffle plates can vary between different baffle plates in dependence upon the position of a baffle plate in the column, or in dependence upon one or more of the following: a solids flow rate at the position, a liquid flow rate at the position, and a gas flow rate at the position. The invention also provides a method for improving the operating performance of an unbaffled column.

-

Froth flotation apparatus

Jiann-Yang Hwang

The froth flotation apparatus includes a gas bubble-particle contact unit including a mixing structure for breaking a gas into fine bubbles,such as a packed tower packing or mechanical agitator, and a separate phase separation unit. A conditioned aqueous pulp containing a mixture of hydrophobic and hydrophilic particles and a substantially inert gas, such as air, are introduced into and combined in one end of the contact unit and subsequently flow concurrently through the mixing structure, such that the gas is broken into fine bubbles which intimately contact and become attached to the hydro- phobic particles. The resulting gas bubble-particle mixture is introduced into the phase separation unit which is operated under substantially quiescent conditions. A concentrate fraction containing primarily hydrophobic particles and a tailing containing primarily hydrophilic particles are discharged from the upper and lower portions of the phase separation unit, respectively. In one embodiment, the phase separation unit comprises a vertical column including one or more slowly rotating paddles in the froth zone to produce a froth having a substantially uniform buoyancy. In another embodiment, the phase separation unit comprises an elongated, generally horizontal tank and includes a skimming assembly for moving froth toward the concentrate fraction outlet.

-

Wet process for fly ash beneficiation

Jiann-Yang Hwang

A wet process for the beneficiation of a fly ash by-product has the following steps: a) forming a slurry mixture of a fly ash material and a liquid; b) gravitationally separating and collecting a first material fraction of the fly ash having a density less than the liquid by skimming off floating slurry material; c) separating a first magnetic fraction from the slurry by subjecting the slurry to a magnetic field of from about 300 gauss to about 10 kilogauss; d) separating the unbumed carbon from the remaining slurry components by adding an effective amount of an oil having a carbon chain greater than octane, and a frothing agent whereby the oil coats the unbumed carbon forming hydrophobic carbon materials and inducing air into the system for frothing the slurry mixture wherein the hydrophobic unbumed carbon froths to the surface and is removed by skimming off the frothing layer; and e) collecting the remaining fraction of silicate spheres and silicates.

-

Regeneration of adsorbents using advanced oxidation

John C. Crittenden, Sawang Notthakun, David W. Hand, and David L. Perram

The present invention is a method of purifying fluid having organic material. The method comprises two operational steps. The first step includes passing the fluid through an adsorbent such that the organic material is substantially adsorbed by the adsorbent and the fluid is substantially purified. The second step includes destroying the adsorbed organic material on the adsorbent and regenerating the adsorbent in a form substantially free of adsorbed organic material.

-

Free-radical retrograde precipitation-polymerization process

Gerard T. Caneba

A free-radical retrograde polymerization process for forming a polymer. An admixture of reactants including predetermined amounts of a monomer, a solvent, and a free-radical-initiator is reacted. A precipitation polymerization reaction occurs such that a polymer-rich phase is at a temperature generally above the lower critical solution temperature (LCST) of the admixture.

-

Interferometric measurement of glucose by refractive index determination

Dale R. Yoder-Short

An apparatus and method for testing the glucose level in a blood sample is provided. The method includes the step of initially filtering a sample of blood to be tested. A beam of light is provided and split into a pair of beams by a beam splitter. The pair of beams travel along generally parallel paths. One path contains a cell of a known optical pathlength and additionally a compensator. The other path has a cell containing the filtered blood sample to be tested. The pair of beams are then recombined by a mirror and a fringe pattern is detected at a detector. From the fringe pattern, the refractive index of the blood sample can be calculated. The refractive index is easily converted to a specific glucose concentration. Alternatively, the original fringe pattern can be restored by changing the effect of the compensator. The refractive index can then be found from the required compensation.

-

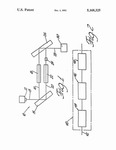

Pallet and apparatus for forming a pallet with deep drawn legs

L. Bogue Sandberg, Bruce A. Haataja, Douglas C. Jurmu, Robert D. Palardy, Frank H. Story, and William A. Yates

A method and apparatus for molding articles such as pallets from flake-like wood particles mixed with binder, the pallets housing a deck and integral molding legs. A loosly fitted mat of wood flakes is formed by depositing a first plurality of layers of wood flakes onto a supporting surface with a flake aligners provided for causing alignment of those flakes which will form legs of the pallet. A second plurality of layers are formed with a flake aligner provided for causing alignment of flakes which will form the legs of the pallet and in a direction transverse to the direction of alignment of the flakes of the first layers.

-

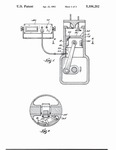

Apparatus for measuring the temperature of a piston in an internal combustion engine

Carl L. Anderson, Glen L. Barna, and Douglas B. Brumm

An apparatus for measuring the temperature of a piston in an internal combustion engine. The apparatus includes a thermistor to sense the temperature of the piston and generate an electrical signal representative of that temperature, a transmission unit connected to the thermistor for receiving the electrical signal and for converting the signal to an infrared beam for transmission to a point remote from the piston, and a receiver to receive the beam and convert the beam to an electrical signal corresponding to the electrical signal generated by the thermistor. The first mentioned electrical signal is converted to a rectangular wave form prior to transmission of the infrared beam.

-

Froth flotation

Jiann-Yang Hwang

A froth flotation apparatus includes a gas bubble-particle contact unit including a mixing means for breaking a gas into fine bubbles, such as a packed tower packing or mechanical agitation means, and a separate phase separation unit. A conditioned aqueous pulp containing a mixture of hydrophobic and hydrophilic particles and a substantially inert gas, such as air, are introduced into one end of the contact unit and flow concurrently through the mixing means, such that the gas is broken into fine bubbles which intimately contact and become attached to the hydrophobic particles. The resulting gas bubble-particle mixture is introduced into the phase separation unit which is operated under substantially quiescent conditions. A concentrate fraction containing primarily hydrophobic particles and a tailing containing primarily hydrophilic particles are discharged from the upper and lower portions of the phase separation unit, respectively. In one embodiment, the phase separation unit comprises a vertical column including one or more slowly rotating paddles in the froth zone to produce a froth having a substantially uniform buoyancy. In another embodiment, the phase separation unit comprises an elongated, generally horizontal tank and includes a skimming assembly for moving froth toward the concentrate fraction outlet.

-

Method for making reshapable articles containing lignocellulose utilizing polyisocyanate resins

Bernard C. Sun

Reshapable composite material and/or articles formed from lignocellulose-containing materials and having improved strength and water resistance characteristics are made by applying about 7 to about 100 weight % of a polyisocyanate resin to fibers and/or fiber bundles of a lignocellulose-containing material. The resulting mixture or furnish is compression molded to form a composite material and/or article of the desired shape and dimensions.

-

Wet process for fly ash beneficiation

Jiann-Yang Hwang

A wet process for the beneficiation of a fly ash by-product has the following steps: a) forming a slurry mixture of a fly ash material and a liquid; b) gravitationally separating and collecting a first material fraction of the fly ash having a density less than the liquid by skimming off floating slurry material; c) separating a first magnetic fraction from the slurry by subjecting the slurry to a magnetic field of from about 300 gauss to about 10 kilogauss; d) separating the unburned carbon from the remaining slurry components by adding an effective amount of an oil having a carbon chain greater than octane, and a frothing agent whereby the oil coats the unburned carbon forming hydrophobic carbon materials and inducing air into the system for frothing the slurry mixture wherein the hydrophobic unburned carbon froths to the surface and is removed by skimming off the frothing layer; and e) collecting the remaining fraction of silicate spheres and silicates.